Valve Body:

The body, few times known as the shell, is the basic pressure boundary of a valve. It serves as the principal components of a valve assembly since it is the framework which contains everything together.

The body, the first pressure boundary of a valve, resists fluid pressure loads from linking piping. It receives inlet and outlet piping by bolted, threaded, or welded joints.

Valve bodies are cast or forged within a variety of shapes. While a sphere or a cylinder would theoretically be the most economical shape to resist fluid pressure while a valve is open, there are several other considerations.

For instance, several valves needed a partition across the valve body to support the seat opening that is the throttling orifice. Along With the valve closed, loading on the body is hard to determine. A valve end links also distort loads on a simple sphere and more complicated shapes. Ease of assembly, manufacture, and costs are further important considerations. Therefore, the basic form of a valve body classically is not spherical, but ranges from simple block shapes to highly complex shapes in that the bonnet, a removable piece to make assembly possible, forms categories of the pressure resisting body.

Narrowing of the fluid passage (venturi effect) is also a general method for decreasing the whole size and cost of a valve. In other examples, large ends are added to the valve for linking into a larger line.

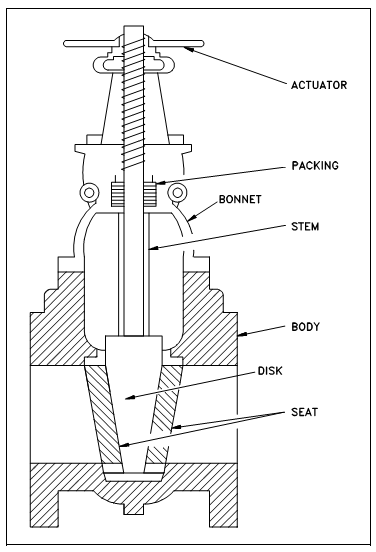

Figure: Basic Parts of a Valve