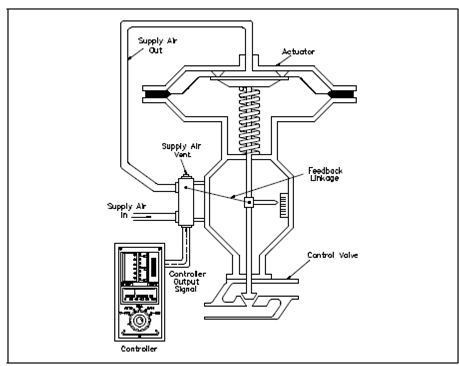

Pneumatic Actuator with Controller and Positioner:

A positioner is a device which regulates the supply air pressure to a pneumatic actuator. It does this through comparing the actuator's demanded position along with the control valve's actual position. The demanded position is transmitted through a pneumatic or electrical control signal from a controller to the positioner. The pneumatic actuator in Figure is display in below Figure within a controller and positioner added.

The controller produces an output signal which represents the demanded position. That signal is sent to the positioner. Externally, the positioner contains of an input connection for the control signal, a supply air output connection, a supply air input connection, a supply air vent connection, and a feedback linkage. Internally, it holds an intricate network of electrical transducers, air lines, linkages, valves, and essential adjustments. Other positioners might also gives controls for local valve positioning and gauges to denotes supply air pressure and control air pressure (for pneumatic controllers). To an operator's viewpoint, a description of complex internal workings of a positioner is not needed. Thus, this discussion will be limited to inputs to and outputs from the positioner.

Within Figure, the controller responds to a deviation of a controlled variable from setpoint and varies the control outcome signal accordingly to correct the deviation. A control output signal is sent to the positioner that responds through increasing or decreasing the supply air to the actuator. The Positioning of the actuator and control valve is fed back to the positioner by the feedback linkage. While the valve has reached the position demanded through the controller and the positioner stops the change in supply air pressure and contains the valve at the new position. That, in turn, corrects the controlled variable's deviation from setpoint.

Figure: Pneumatic Actuator with Controller and Positioner