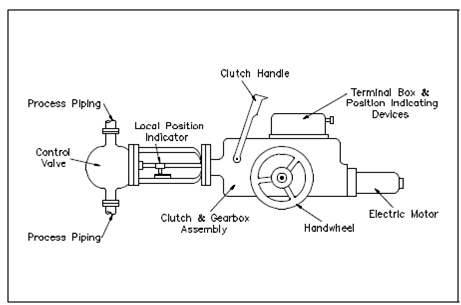

Electric Motor Actuators

Electric motor actuators vary hugely in their design and applications. A few electric motor actuators are designed to operate in only two positions (fully open or fully closed). Other electric motors could be positioned among the two positions. A classical electric motor actuator is display in Figure. Its main categories involve an electric motor, manual handwheel, clutch and gear box assembly, and stem linked to a valve.

Figure: Electric Motor Actuator

The motor moves the stem by the gear assembly. It reverses its rotation to either open or close the valve. A clutch and clutch lever disconnects the electric motor from the gear assembly and permits the valve to be operated manually along with the handwheel.

Many electric motor actuators are equipped within limit torque limiters, switches, or may be both. Limit switches de-energize the electric motor while the valve has reached a specific position. The torque limiters de-energize the electric motor whenever the amount of turning force has reached a specified value. The turning force generally is greatest when the valve reaches the fully open or fully closed position. These characteristics could also avoid damage to the actuator or valve if the valve binds in an intermediate position.