The Problem of Brittle Failure

A number of accidental failures of ships throughout Second World War drew attention of metallurgist and engineers on the problem of brittle fracture. The said ships had all failed presenting brittle fracture in which the crack propagated suddenly with no any plastic deformation and producing loud report because of sudden strain energy's release. As like a result fracture tendency in material in steel enhances because of:

- a triaxial state of stress,

- low temperature, and

- High strain rate or rapid rate of loading.

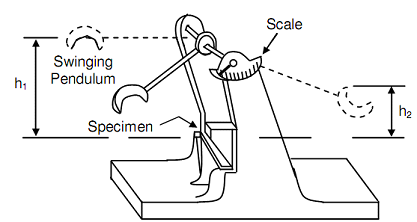

This has been documented that mainly brittle failures in service situation take place for the reason of combined effects of triaxial state of stress, like existing on a notch and low temperature. However, these effects are, accentuated, via high strain rate, thus the laboratory tests combining these entire three situations are performed to find out tendency of a material to fail in brittle manner. That type of tests termed as impact tests are performed in impact testing machine - one that machine is demonstrate in following figure.

Figure: Charpy Impact Testing Machine