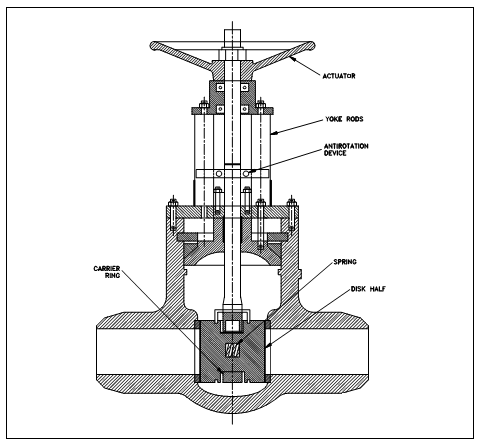

Parallel Disk:

The parallel disk gate valve described in Figure is designed to avoid valve binding because of thermal transients. This design is used within both low and high pressure applications.

The wedge surfaces among the parallel face disk halves are caused to press together below stem thrust and spread apart the disks to seal against the seats. The tapered wedges might be category of the disk halves or they might be separate elements. The lower wedge might bottom out on a rib at the valve bottom so that the stem can develop seating force. Within one version, a wedge contact surfaces are curved to keep the point of contact close to the optimum.

In other parallel disk gates, two halves do not move apart under wedge action.

Alternatively, the upstream pressure contains the downstream disk against the seat. A carrier ring lifts the disks and a spring or springs contain the disks apart and seated while there is no upstream pressure.

The other parallel gate disk design gives for sealing just one port. Within these designs, the high pressure side pushes the disk open (relieving the disk) on the high pressure side, other than forces the disk closed on the low pressure side. Along with such designs, the amount of seat leakage tends to reduce as differential pressure across the seat increases. Those valves will commonly have a flow direction marking that will displays that side is the high pressure (relieving) side. Care should be taken to ensure which these valves are not installed backwards within the system.

Figure: Parallel Disk Gate Valve

A few parallel disk gate valves used in high pressure systems are made along with an integral bonnet vent and bypass line. The three-way valve is be used to position the line to avoid in order equalizing pressure across the disks prior to opening. While the gate valve is closed, a three-way valve is positioned to vent the bonnet to one side or the other.

This avoids moisture from accumulating within the bonnet. The three-way valve is positioned to the high pressure side of the gate valve while closed to ensure in which flow does not bypass the isolation valve. A high pressure acts against spring compression and forces one gate off of its seat. A three-way valve vents this flow back to the pressure source.