Gate Valves:

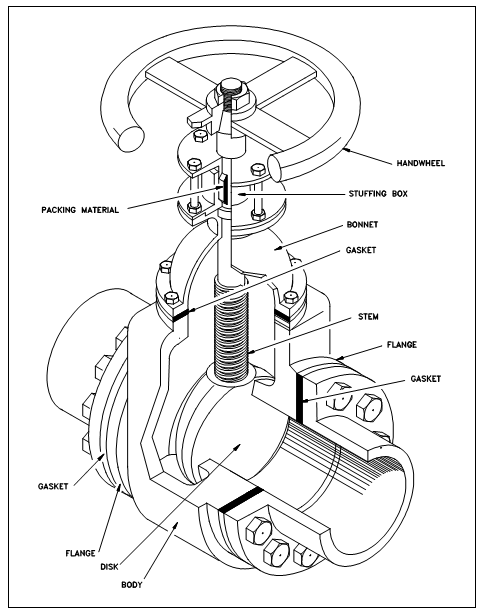

A gate valve is a linear motion valve used to begin or end fluid flow; however, it does not regulate or throttle flow. A name gate is derived from the appearance of the disk within the flow stream. Below figure described a gate valve.

The disk of a gate valve is wholly erased from the flow stream while the valve is fully open. This feature offers virtually no resistance to flow while the valve is open. Therefore, there is little pressure drop across an open gate valve.

While the valve is fully closed, a disk-to-seal ring contact surface exists for 360°, and good sealing is given. Along with the proper mating of a disk to the seal ring, extremely little or no leakage occurs across the disk while the gate valve is closed.

Figure: Gate Valve

While opening the gate valve, the flow path is enlarged in a highly nonlinear manner along with respect to percent of opening. That means which flow rate does not change evenly along with stem travel.

Also, a partially open gate disk tends to vibrate from the fluid flow. Many of the flow modifications occur near shutoff within an associatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. For these purpose, gate valves are not used to throttle or regulate flow.

A gate valve could be used for a huge variety of fluids and gives a tight seal while closed. The main drawback to the use of a gate valve is:

1. It is not suitable for throttling applications.

2. It is prone to vibration within the partially open state.

3. It is more subject to seat and disk wear than a globe valve.

4. Repairs, such as lapping and grinding, are commonly more difficult to accomplish.