Kanban Production Control Systems:

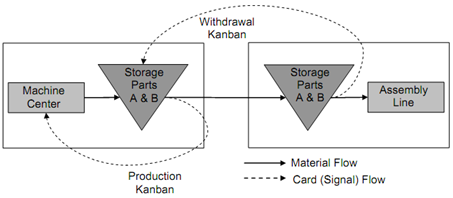

A Kanban control system utilizes a signaling mechanism to control JIT flows. In a paperless control system, containers can be utilized as a substitute of cards. The cards or containers build up the Kanban pull system. The authority to manufacture or provide additional parts comes from downstream operations. Figure illustrated an assembly line that is supplied with parts by a machine centre. The machine centre makes two parts A and B. These parts are kept in containers next to assembly line and next to the machine centre. Each container next to assembly has a withdrawal Kanban, and each of the containers next to the machine centre has a production Kanban. This system is called as two-card Kanban system.

Figure: Flow of Two Kanbans

While the assembly line takes the first part A from a full container, an employee takes the withdrawal Kanban from the container, and takes the card to the machine centre storage area. In the machine center area, the worker discovers a container of part A, eliminates the production Kanban, and replaces it with a withdrawal Kanban. Placement of this card on the container authorizes the movement of the container to the assembly line. The freed production Kanban is placed on a rack by the machine centre, which authorizes the production of another several material.