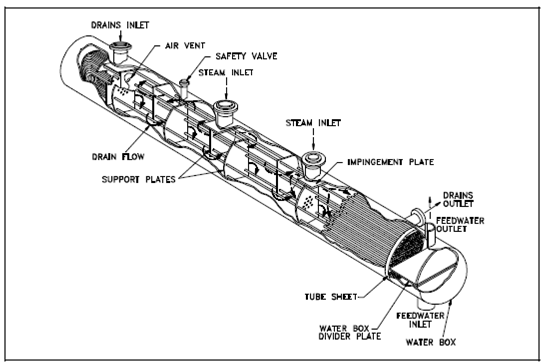

Tube and Shell:

The most basic and the most general category of heat exchanger construction are the tube and shell, as display in below Figure. This category of heat exchanger consists of a set of tubes in a container known as a shell. The fluid flowing within the tubes is known as the tube side fluid and the fluid flowing on the outside of the tubes is the shell side fluid. At the ends of the tubes, the tube side fluid is separated from the shell side fluid through the tube sheet(s).

A tube is rolled and press-fitted or welded into the tube sheet to give a leak tight seal. In systems whereas the two fluids are at vastly variant pressures, the higher pressure fluid is classically directed by the tubes and the lower pressure fluid is circulated on the shell side. This is because of economy, since the heat exchanger tubes could be made to withstand higher pressures than the shell of the heat exchanger for a much lower cost. The support plate's displays on Figure also act as baffles to direct the flow of fluid inside the shell back and forth across and the tubes.