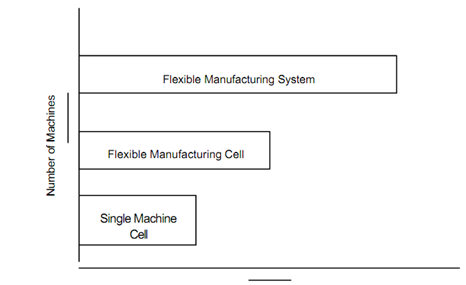

According to the Number of Machines

The following are distinctive categories of FMS according to the number of machines in the system:

Single Machine Cell (SMC):

This consists of a complete automated machine capable of unattended operations for a time period longer than one machine cycle. This is capable of processing different part styles, responding to modification in production schedule, and accepting new part introductions. In this, processing is sequential not simultaneous.

Flexible Manufacturing Cell (FMC):

This has two or three processing workstation and a part handling system. The part handling system is associated to a load/unload station. This is capable of simultaneous production of different parts.

A Flexible Manufacturing System (FMS):

This has four or more processing work stations (normally CNC machining centres or turning centres) associated mechanically by a common part handling system and automatically by a distributed computer system. This also includes non- processing work stations that support production however does not directly participate in it, for example part / pallet washing stations, co-ordinate measuring machines. These features considerably differentiate it from Flexible manufacturing cell (FMC).

Annual Production, Flexibility, Cost Incurred

Figure: Comparison for Three Categories of FMS