Milling Fixture

This contains the part in correct relation to the milling cutter. Fixture is attached to milling machine table. Milling fixture consists of the base, rest blocks, clamps, or nest, locating points & gauging surfaces.

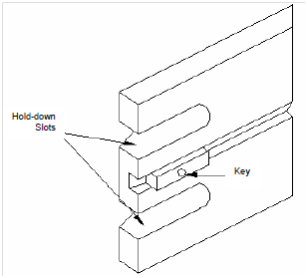

The base of milling fixture consists of a base plate. A base plate has a flat and accurate undersurface and forms major body on that several elements are mounted. This surface aligns with the surface of the mill table and forms the reference plane with respect to the mill feed movement. It may be constructed of steel plate/cast iron, depending upon the size and complexity of the part. The slots are given in the base for clamping the fixture to the mill table. The base plate of the surface also has keyways along with length of the base for two keys. Those keys are used to align the fixture on the milling machine table. The keys are pressed within the keyway at both ends of fixture and held there through socket head caps screw. This arrangement is display in Figure. It is essential to adjust the table through using feed movements until the correct position is attained. This can be completed through trial and error cuts in the workpiece. Milling is always first operation for that.

Figure: Underside of Milling Base

One must know the dimension of milling machine for designing the fixture. The several dimensions involve the dimension of centre-to-centre distance of T-slot, T-slots, dimension of milling machine table and length of table travel in all three feed movements. Tool designer should give sufficient clearance space around hold down slots for a nut, wrench and washer. Clamps on mill fixture must be very rigid.

Cutting forces might change as the cutter enters or leaves the workpiece and throw an extra load on clamps. Clamps should not be loosened through vibrations that are caused by interrupted cutting by the mill cutter at the beginning and at the end of the cut. Clamp should be situated opposite to bearing surfaces and locating points. These should be designed in a way so which these can be simply operated through the operator.

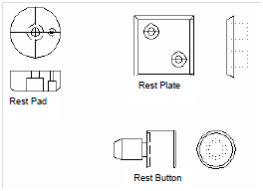

Rest blocks/bearing surfaces are located along with the nest and give support for the workpiece. These surfaces change within design according to the shape & size of workpiece. These are commonly in the form of pins, plates or pads which are accurately placed in the base of fixture as display in above Figure. These surfaces are raised above the surface of base to allow chips to fall away and permit simple cleaning.