Combination Dies

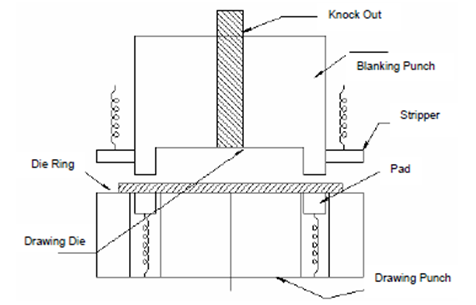

In a combination die, cutting action is combined along with non-cutting actions that is forming. Non-cutting actions may be bending, drawing, extrusion or embossing. Much more than one operation is probable in one stroke at a single stage, but the die is more helpful for two operations only. The principle of working of a combination dies is displayed in below diagram.

Figure : Combination Die

The die ring is mounted on the die shoe. The die ring is counter bored at the bottom to permit the flange of a pad to travel up and down. This pad is held flush along with the face of die by a spring. The drawing punch of needed shape is attached to the die shoe. The blanking punch is located in the punch holder. The stripper (spring operated) strips the skeleton from the blanking punch. Since the work-piece comes in contact along with the knock out bar during the return stroke, knock out eliminates the part attached to the punch. Since the part is blanked, the blank holding comes down. After that the drawing punch contacts and forces the blank into the drawing die that is made into the blanking punch.