Push Systems:

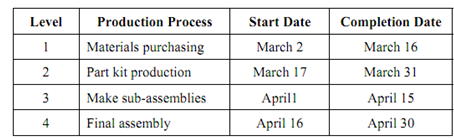

This system chiefly work by extracting information from the suppliers, customers to manage the flow of materials. The raw materials are arrived at the factory only when they required making batches and sub-assemblies. These batches and parts are proceeding for final processing, while they are needed. Furthermore, these finished parts are assembled and shipped only while they are demanded by the customers. This way the entire production process takes place by the action of a force that tends the raw materials to be processed according to their demand. Instances of this type of production and control system can be given as: imagine an order of 100 parts have been demanded by the customers on April 30 and suppose each sub-production process takes 2 weeks to finished. Then, the schedule shall be as follows) :

Table: Starting and Completion Time of Production Process

The accuracy of schedule plays a vital role in effective production of the parts. And the accuracy of the schedule based upon the information that is flowing in the system. The great achievement of the push production and control system is the reduction in raw-materials inventories along with the greater utilization of all of the production units (that means machine and labour).