Rotodynamic Pump

A roto-dynamic pump has a wheel or a rotating component which rotates the water in casing thus increasing the energy level due to a combination of centrifugal energy, pressure energy and kinetic energy.

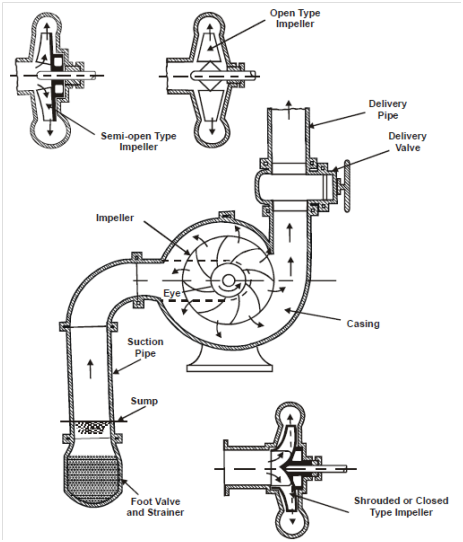

A centrifugal pump is the most common among the rotodynamic pumps. Unlike a positive displacement pump, in which the liquid is simply pushed out of the pump, a centrifugal pump modifications the hydraulic energy such that the liquid is lifted to a higher level. The primary principle on which a centrifugal pump works is that while a certain mass of liquid is made to rotate through an external force that is thrown outwards from the axis of rotation or a centrifugal head is impressed on it. This enables the liquid to rise to higher stages. If more liquid is made available at the centre of rotation, a continuous supply of the liquid to the higher level may be ensured. The mechanism by which a liquid is made to rotate consists of a revolving wheel with vanes, which is known as an impeller. During the passage of the liquid through the impeller, angular momentum changes, and this circumstance also results in the increase of the pressure head of the liquid.The major parts of centrifugal pump that is impeller, casing, vortex chamber, guide vanes, suction pipe and delivery pipe are shown in Figure.

Figure : Component Parts of Centrifugal Pump

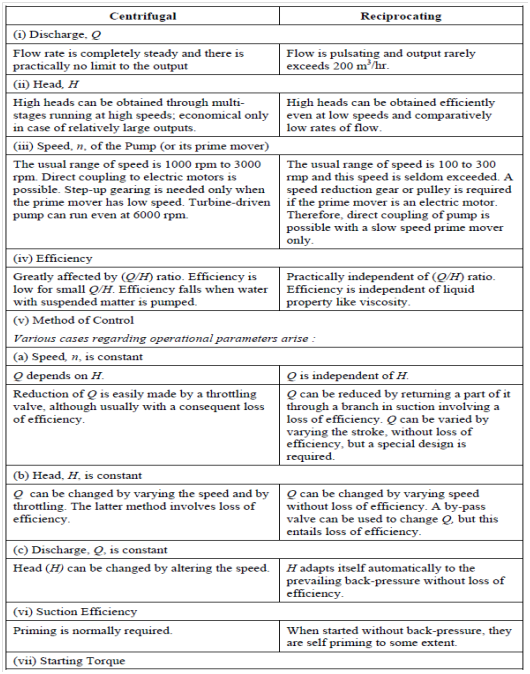

The main advantages of a centrifugal pump over a reciprocating pump are the former’s larger discharging capacity. A centrifugal pump can also be used to pump turbid (muddy) waters which may damage the valves of a reciprocating pump. A centrifugal pump is commonly connected directly on to an electric motor or an oil engine, although a reciprocating pump needs a speed reduction mechanism, like a pulley and a belt drive. Table 1 compares the important differences in operating characteristics of centrifugal and rotodynamic pumps.

Table 1: Important Differences in Operating Characteristics of Centrifugal and Reciprocating Pumps