Grit Removal

Wastewater usually contains a relatively large amount of inorganic solids such as cinders, sand, and gravel that are collectively known as grit. The amount present within a particular wastewater depends primarily on whether the collecting sewer system is of the sanitary or merged type. Grit will damage pumps through abrasion and cause serious operation difficulties within sedimentation tanks and sludge digesters through accumulation around and plugging of outlets and pump suctions. Therefore, it is common practice to erase this material through grit chambers.

Grit chambers are commonly located ahead of pumps or comminuting devices, and if mechanically cleaned, should be preceded through coarse bar rack screens. Grit chambers are commonly designed as long channels. In these channels, the velocity is reduced satisfactorily to deposit heavy inorganic solids but to retain organic material in suspension. Channel kind chambers should be designed to give controlled velocities as close as possible to 0.3 meter per second. Velocities substantially smaller than 0.3 meter per second cause excessive organic materials to settle out along with the grit.

The detention period is commonly among 20 seconds to 1.0 minute. This is attained by giving several chambers to accommodate variation in flow or through proportional weirs at the end of the chamber or other flow control devices that allow regulation of flow velocity.

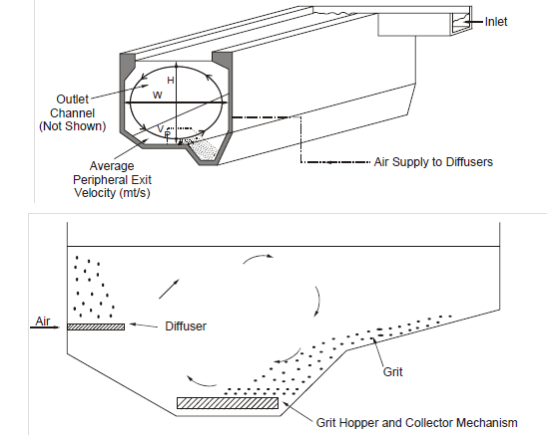

One development is the injection of air above the floor of a tank type unit. The rolling action of the air keeps the lighter organic matter in suspension and permits the grit associatively free from organic matter to be deposited in the quiescent zone beneath the zone of air diffusion. Excessive quantities of air could cause the roll velocity to be too high resulting within poor grit removal. Not sufficient quantities of air result in low roll velocities and excessive organic matter will settle along with the grit. These grit chambers are commonly called aerated grit chambers (Figure 3).

Figure 3: Aerated Grit Chambers

Grit chambers are designed to be cleaned manually or through mechanically operated devices. If it is cleaned manually, storage space for the deposited grit is generally given. Grit chambers for plants treating wastes from merged sewers should have at least two hand-cleaned units or a mechanically cleaned unit along with by-pass. Mechanically cleaned grit chambers are optional. Single, hand-cleaned chambers along with by-pass are acceptable for little wastewater treatment plants serving sanitary sewer systems. Chambers another than channel type is acceptable if it provide along with adequate and flexible controls for agitation and/or air supply devices and with grit removal equipment. There are a single number of mechanical cleaning units available that remove grit through scrapers or buckets although the grit chamber is in normal operation. These needs much less grit storage space than manually operated units.

Grit always holds some organic matter that decomposes and creates odours. To facilitate economical disposal of grit without causing nuisance, an organic matter is sometimes washed from the grit and returned to the wastewater. Here the special equipment is available to wash grit. Mechanical cleaning equipment commonly gives for washing grit with wastewater, as it is erased from the chamber.

Manually cleaned grit chambers for merge wastewater should be cleaned after each large storm. Under ordinary conditions, these grit chambers should be cleaned while the deposited grit has filled 50 to 60 % of the grit storage space. This should be checked at least each ten days during dry weather. While mechanically cleaned grit chambers are used, they must be cleaned at regular intervals to avoid undue load on the cleaning mechanism. Recommendations of the building should be rigidly observed. That plus experience, will determine the cleaning schedule. Grit in that marked odours develop denotes in which excessive organic matter is being removed within the grit chamber. Instead, if sludge from a settling tank is excessively high in grit, or if there is excessive wear within pumps, comminutors, sludge collectors or other mechanical equipment, the purpose is likely to be inefficient functioning of the grit removing process.