Zero Breakdowns

Physical condition of equipment deteriorates due to many reasons, one of them is usage. The deterioration could be external (visible) or internal (invisible). If the deterioration or decay or defects are not noticed in right time, the equipment breaks down. Therefore, the plant engineer is required to go on keen observation of the equipment conditions regularly so as to forestall the occurrence of any breakdown. To achieve zero breakdown (i.e. no breakdown) the important steps are listed below:

- Rectify design deficiency (as soon as it is identified).

- Rectify the deterioration so as to bring the condition nearest to its original state.

- Stick to optimum operating conditions (as prescribed by OEM in the manual).

- Maintain the basic equipment conditions (by proper and timely cleaning, lubricating, bolt tightening, etc.).

- Improve maintaining and operating skills.

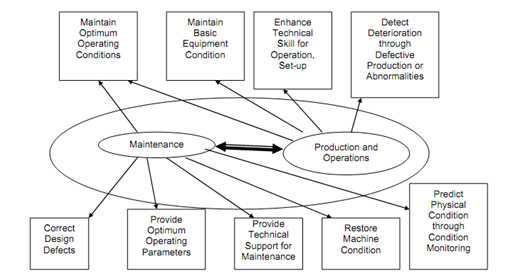

Figure: Role of Maintenance and Operations Departments in Materialising Zero Breakdowns

The given Figure shows the role of maintenance and operations departments in achieving zero breakdowns. However, it is believed that the zero breakdowns can be achieved by two facet approach, i.e. a part of the job by maintenance and another part by production.

The maintenance personnel should perform the following functions :

- Provide optimum operating parameters and clear instructions to the production department for safe functioning of the machinery.

For Example

- The maximum temperature of cooling water. Instruct that if the temperature exceeds a given value, the machine should be put off.

- Provide the information regarding the maximum pressure that a compressor should develop.

- Provide technical support to the production department for its autonomous maintenance activities.

- Restore deteriorated condition to normal condition, using inspection, overhauling and replacement.

- Predict status of the physical condition through condition monitoring techniques and take preventive steps if there are any symptoms of occurrence of breakdown or faulty production.\

- Enhance maintenance skills for routine check-up and minor maintenance and repair work.

- Correct minor design defects if possible, otherwise warn the production manager of the fault so that the machine may not be operated, otherwise defective product will come out.

The production personnel have to perform the following functions:

- Basic maintenance functions such as cleaning, checking of lubricant, water, grease, tightness of nut, screw, etc.

- Detect deterioration in functional performances through wear debris size and/or size distribution, product quality, noise level, smoke level, temperature of cooling water, consumption of lubricating oil, grease, etc.

- Maintain operating conditions as specified in equipment manual given by OEM or as suggested by maintenance department.

- Enhance technical skill for set-up, operation, adjustments and visual inspection.