Hardness

Hardness of a material is its capability to resist indentation or scratching. This property is the measure of resistance to wear and abrasion. Both indention and scratch methods are utilized for determining this property. For engineering reasons indentation method is utilized.

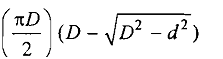

The load that is utilized to cause indentation on a flat surface by an indenter is divided by surface area of indentation to acquire a number that is called hardness number. A ball of 10 millimeter diameter made in hardened steel is utilized as an indenter beneath a load of 30000 N and kept applied for 30 sec. There of indentation is:

With D as diameter of the ball and d as the diameter of impression upon flat surface Different loads are utilized for various materials. Brinell hardness number is the ratio of load P and area of indented surface as described above. Instead of utilizing the area of surface of indentation of divide the load P to acquire harness number one can use the area of circular impression on the surface or the projected area or the depth of indentation directly can be utilized as an indicator of hardness. The former is utilized to determine Meyer hardness number while latter is utilized with a different (conical) indentor for Rockwell hardness number. Rockwell hardness uses various loads and indentors for having different Rockwell scales. Rockwell C is commonly utilized for steels. Rockwell method is usually preferred over Brinell since it does not need a finished surface, this can be determined on a finished part along with no spoiling the surface and it provides the reading of hardness directly. Rockwell method measures the depth of the indentation and hardness, called Rockwell hardness number is inversely proportional to the depth of indentation.

This is no wonder that a relationship exists among hardness of a material and its strength since both are related to bonding forces at atomic level. Due to nature of stress in a hardness test being complex (tri-axial) and effect of friction creeping in because of contact between the indentor and the specimen such relationship is difficult to establish.

Conversely, empirically the ultimate tensile strength and Rockwell c hardness are associated as

σu = 33 rc

This is also interesting to note that techniques, which raise the ultimate tensile strength of material, also increase the hardness. Increase in strength and hardness is associated with decrease in ductility as %age elongation and raise in yield or proof strength and consequent increase in modulus of resilience. For such reason hardness is often utilized in lieu of elaborate tension test for characterizing a material or checking effectiveness of any type of treatment. Hardness is utilized also for calculating UTS (su) in design.

This may also be mentioned here that while the treatments described to material may alter yield strength ultimate tensile strength, hardness and %age elongation. The module of elasticity will keep unchanged. That's why the constants of material are to be differentiated from mechanical properties.