Creep

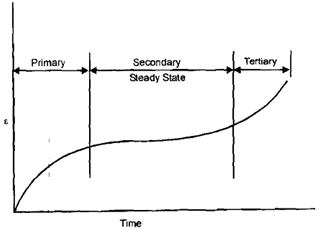

Yet other important behaviour of material arises while the material is subjected to a constant load over a long time. This is found that a body of material subjected to a load which causes stress less than yield strength, over a long period of time. Undergo a deformation that increase as time possesses. The strain so created may ultimately reason the failure. The behaviour of material is termed creep and the strain is termed as creep strain. The rate at which strain raises will decide after what time the material will fail. At higher stress the strain rate will be higher and conversely. This may be noted from the definition given here that the temperature is not a requirement for creep deformation to occur. Creep happens at all temperatures. Conversely, the creep rate is accelerated along with increasing temperature and at temperature which is close to half of melting point temperature on absolute scale; creep becomes an significant consideration in design. Hence theoretically though higher temperature is not an essential condition for creep yet at higher temperature it is a real problem. The creep rate at constant temperature rises along with increase in stress and qt constant stress it increases along with increase in temperature. The characteristic creep curve is plotted between creep strain and time and is characterized by three stages as shown in diagram. A designer would prefer to load a machine part in such a way that only secondary creep having a constant creep rate sets in. Tertiary creep is characterized by raising creep rate and fast ends in fracture. Creep becomes an important consideration in gas turbine blading design because temperature is high. In gas turbine, the higher limit of temperature is limited due to creep of blading material.

Diagram: Creep Curve that have 3 Stages of Creep are depicted

Sometime a quantity as like creep strength is defined as a stress at a specified temperature which will produce minimum creep rate of a specific amount usually 0.000 1 %/hour. Creep rupture strength is stresses at described temperature, which will reason rupture after predefined life in number of hours say I0, 000 or 1000 hours. Rupture is theoretically fractured happening with X-sec. reduced to zero. Both creep rupture strength and creep strength are arbitrary and not utilized in design except for comparing two materials.

A consequence of creep is a phenomenon named as stress relaxation, which refer to decrease of stress at constant strain. Difficulty of stress relaxation is common in bolts utilized to clamp two parts at higher temperature. For illustration, bolts utilized to clamp cover on a pressure vessel, at high temperature might lose stress after some time and hence clamping force gets reduced.

Addition of 0.5% Mo and 0.1 % C and 1.25% cr in steel enhances creep resistance. Addition of Cr in varying proportion with Mo in steel assist enhances creep resistance. Nickel base alloys as like Inconel as C-0.04, Cr-I 5.5, Fe- 7.0, and Ni-76 have high creep resistance. Cobalt base super alloys are also utilized for various purposes against creep.