Milling Operations

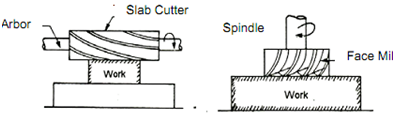

Plain or Slab Milling

It is the process of producing flat surfaces on a horizontal milling machine. The surface milled is parallel to the axis of the cutter. As usual work is fed past the revolving cutter.

Face Milling

It is a process of producing flat surfaces on a vertical milling machine. The surface machined is at right angles to the axis of the cutter. Depth of cut is adjusted by rotating the cross-feed screw.

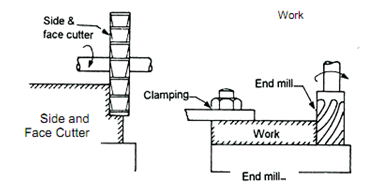

Side Milling

It is the process of producing a flat vertical surface on the side of workpiece. It makes use of side milling cutter.

End Milling

It is the process of producing flat surfaces which may be horizontal, vertical or at an angle with respect to table position. This operation makes use of end mill on a vertical milling operation to cut slots, grooves keyways, etc. However, plain and side milling cutters can also be employed.

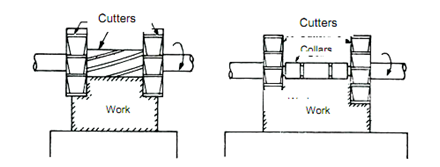

Gang Milling

This is an operation of producing (machining) several surfaces at a time. Two or more cutters of same or different sizes are mounted on the same arbor and work is fed against them. Gang milling is widely used in repetitive work. Cutting speed is calculated

(c) Side Milling (d) Milling

(e) Gang Milling (f) Straddle Milling

(g) Form Milling (h) Angular Milling

Figure 10 : Various Milling Operations and the Cutters Used

Straddle Milling

In side milling cutters mounted on the same arbor, can machine two vertical flat sides of a workpiece at the same time, the operation is called straddle milling. The pair of cutters are spaced accurately using spacing collars. This operation is very common in industries to produce parallel surfaces.

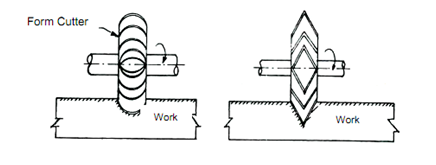

Form Milling

It is the process of milling irregular surfaces. The operation is carried out on a horizontal milling machine by using a form milling cutter. This cutter will have teeth corresponding to the profile of the surface to be produced.