Tool Supply Systems

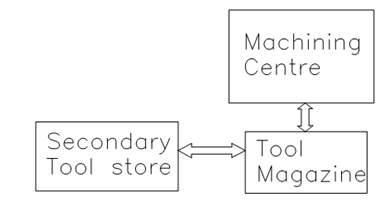

In an automated manufacturing system, cutting tools must be taken out and supplied into the system at intervals depending on their uses. If one considers the stand-alone machining centre (diagram 21), tool magazine of the automatic tool changer be supplied at the starting of the shift, all the tools in refurbished condition. The secondary tool store in this case could be the tool crib itself by which the tools are transferred manually at periodic intervals. If any of the tools has to be altered during the operation, then the machine tool may must be stopped for changing. This would be expensive in terms of the lost production time on the machine, and therefore alternative better means have to be found for replenishing the tools in the system. The tools need to be replaced when the machine is cutting.

Figure 21: Tool Supply Management for a Machine Tool in a FMS

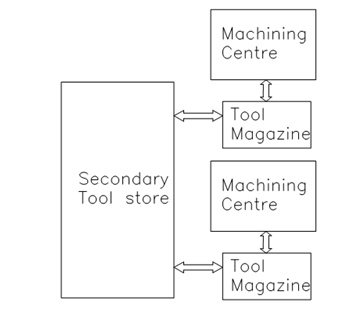

But with some machine tools, the problem gets compounded further. As wellin FMS, whenever the part spectrum to be manufactured gets changed, the tooling needed may have to be altered accordingly. Therefore more and varied solutions have been tried by several machine tool manufacturers. A brief comparison of these systems is presented in Table 4. The basic concept in all the systems is to get secondary (auxiliary) tool storage from in which the required tools can be transferred to the main tool magazine automatically where and when essential without much effort and loss of cutting time as shown in Figure 22.

Figure 22: Tool Supply Management for a Number of Machine Tools in a FMS

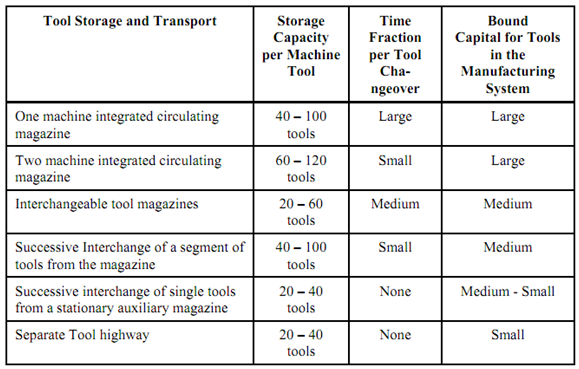

Table. 4 : Tool Supply Concepts in Manufacturing Systems