Tool Inventory Cost

This is the cost of carrying inventory of a particular type of tool to ensure that the work is not held up for want of tools.

The inventory of tool at any given instant consists of:

(a) Number of tools at machine.

(b) Tools in transit between grinding room and machine.

(c) Stock of ready reground tools or stock of tool holders and inserts in the tool crib.

(d) Those in the process of grinding.

Inventory carrying rate consists of interest on money invested in the tools, storage cost etc., approximately 20% of purchase price per year.

Tool Inventory Cost

Total inventory of tools × Cost per tool × Inventory cost rates

These costs can be demonstrated with the help of a simple turning operation. Let us assume turning of a bar of length L mm and diameter D mm, with a cutting speed of V m/min, feed rate of f mm/rev, and depth of cut of d mm.

Time for machining is given by

Tm = L/ f N

Where N is the spindle RPM which is related to cutting speed by the following relation.

V = π DN/1000

Substituting this into the previous equation, we get

Tm = π DL /1000 f V

For a specified job, the cost of all overheads is given by:

Equation

C1 = C0 [p (t1 + tu1 + ta) + t0]

Where t0 = tool advance and withdrawal time,

tl = job loading time,

tul = job unloading time,

t0 = initial setup time of the machine for a batch of components, and

p = number of parts produced per batch.

For evaluating the tool cost, we have to consider the initial cost, the cost of regrinding, the number of regrinding possible in case of HSS tools, the time taken for indexing and the number of indexable edges available in case of carbide tools.

For carbide and ceramic tools with throwaway tips,

C e = Cost of the bit / Number of cutting edges per bit

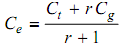

For HSS and brazed carbide tools,

Ce = Cost of tool + regrind cost × Number of regrinds/ Number of regrinds + 1

Where Ct = initial cost of the tool,

r = number of regrinds possible for one tool,

Cg = cost of regrinding the tool, and

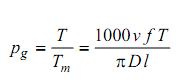

Pg = number of components produced between regrinds = T/Tm. where T is the useful life of the tool

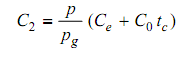

Cost of tool replacement = p C0 Tc/ Pg

Where tc = tool change time

Thus the total cost of the tool is

The machining cost C3 is given by

C3 = C0 p Tm

Now combining all the components of costs, we get the cost per batch CB as

CB = C 0 [p (t1 + tu1 + ta) + t0 ]+ p/pa(Ce + tc C0 ) + C0 p Tm

Likewise, the cost per piece of production is given by

Cp = [C0 t1 + tu1 + ta + t0 /p ] +1/ pg ( Ce +tc C0 )+C0 Tm

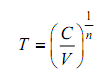

Considering Taylor's tool life equation,

VT n = C

The number of pieces produced per regrind is

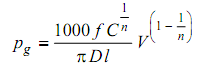

From the tool life equation,

Thus,

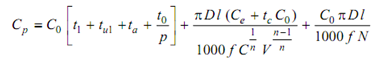

The cost per piece, Cp is given by

The above equation is the basic equation with which we can derive the optimal cutting speed and time for the conditions of minimum cost and maximum production rate. It is applicable for single pass, single tool, constant speed machining operations (e.g. longitudinal turning). It will require to be modified to accommodate other situations in machining like face turning, multi tooth cutting, etc.