Tolerance or Cost Relationship

Tolerance is a key factor in finding the cost of a part. The manufacturing (total) cost is divided into machining and scrap cost. The machining cost is the cost of primary producing the part. This cost includes labour, gauges, overhead, tools, jigs and fixtures, inspection, etc. The scrap cost is the cost encountered because of rejecting some parts that fall outside the specified tolerance range, and/or because of repairing some of these parts.

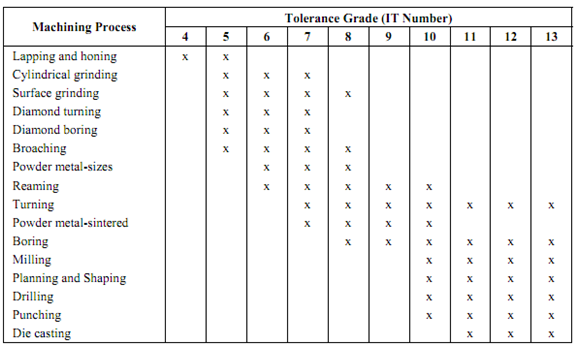

It is significant for designers to be aware of manufacturing accuracies achievable by various manufacturing processes. To assist designers in relating tolerances to machining processes, Table 3, developed by ANSI, relates tolerance grades (IT number) to machining processes. The range of grades for each of process accounts for the conditions (new, old, well maintained, etc.) of the machine, and the level of skills possessed by the machine operator. Having chosen a tolerance depend on functional requirements of a part, the designer might determine the tolerance grade for a specified size by using tolerance grade tables. With the tolerance grade known, the designer might determine the proper machining process by using Table 3. With the knowledge presented in Table 3 and the tolerance grade table, the designer can effectively judge the manufacturing method to produce the design.

Table 3: Relationship among Tolerance Grades & Machining Processes