Estimation of Machining Time in Milling

The following factors are to be considered in estimating the machining time in any type of milling operation:

(a) Total length of job to be machined.

(b) Approach - i.e., the distance through which the cutter has to move before the full depth of cut is acquired. This ensures smooth entry of tool into the workpiece and thus, improves both tool life and the job accuracy.

(c) Over run - i.e., the distance through which the cutter has to move further after the job length is over, to be clear of the job. Its purpose is similar as enumerated earlier.

(d) Number of cuts.

(e) Cutting speed.

(f) The amount of feed per minute.

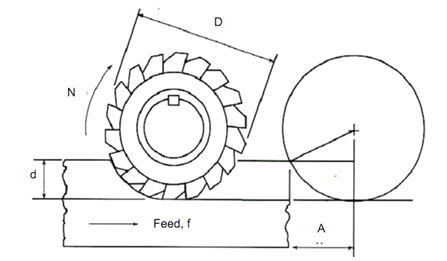

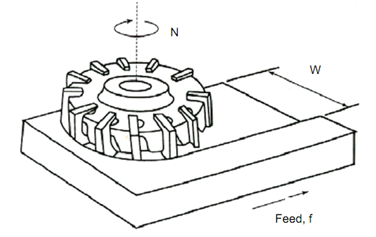

Figures 2 and 3 show milling operations being performed by using the plain and face milling cutters respectively.

Let l = length of the job to be machined in min.

Figure 2 : Slab Milling Operation

L = l + 2 × A

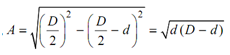

Now, in plain milling, if D mm be the diameter of the cutter and d mm be the total depth of the cut, then the approach A is given by :

Approach distance,

Equation 1

Figure 3 : Face Milling Operation

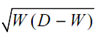

Now refer to Figure 3, that means face milling. Let W mm be the width of the job and D mm the diameter of the cutter, then the approach in this case is given by :

A = D/2 mm for W = D/2 up to D

A =

mm for W < D/2

mm for W < D/2

Equation 2

Time for one pass = (l + 2 × A) / f Z N minutes

where Z = no. of teeth in the milling cutter, and

f = feed per tooth, mm.

Now, if n be the number of cuts and f the feed in mm per minute, then the machining time T in minutes can be calculated from :

Equation 3

T = (L × N )/ f Z N minutes

For determining the total floor time, handling time must be added to the actual machining time calculated above.