Estimation of Machining Time in Drilling

Typical process parameters used in drilling operations are given in Table 1. The cutting speed in drilling is the surface speed of the twist drill. Thus,

V = π DN /1000

Where V = cutting speed (surface), m/min

D = diameter of the twist drill, mm

N = rotational speed of the drill, rev/min

The drill will have to approach the start of the hole from a distance and also traverse beyond the actual hole by a distance termed as the total approach allowance A. The initial approach is generally a small value for positioning the drill above the hole. This distance AI can generally be taken as 2 to 3 mm. The traverse distance beyond the hole is often termed as the breakthrough distance and is required because of the conical shape of the twist drill. This value is dependent upon the drill diameter and the lip angle and is given by:

For drilling blind holes breakthrough distance = 0 (zero).

Breakthrough distance

A = D/2 tan α

For the most common case of α = 59o, it is given by

A = D/3.3286

Total length of tool travel L = l + A + 2 mm

Where l = length of the hole, mm

Equation 1

Time for drilling the hole = L/ f N minutes

Where f = feed rate, mm/rev.

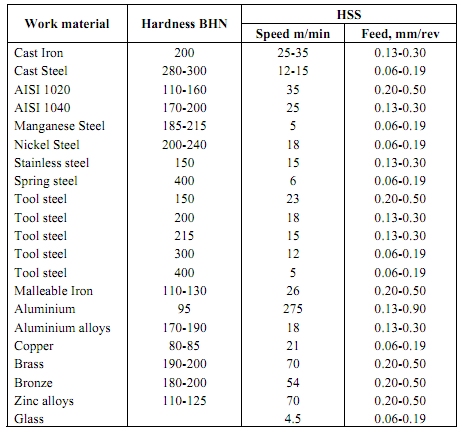

Table 1: Cutting Process Parameters for Drilling

The material removal rate is indicated by the total volume of the material in the hole. In the case of a solid material without coring, the material removal rate MRR is given by the area of cross-section of the hole times the tool travel rate through the material. Thus

Equation 2

MRR = (π D2 f N) /4