Estimation of Machining Time for Shaping

Let L = Length of stroke or Tool travel, in metres,

l = Length or breadth of job, over which the tool passes, in metres,

l1 = Tool approach, that means. the distance it has to travel before starting actual cutting in metres,

l2 = Overtravel, i.e. the distance through which the tool travels beyond the work surface in metres,

f = Feed per cycle, in mm,

m = Ratio of return time to cutting time,

v1 = Average cutting speed, in metres per min.,

v2 = Average return speed, in metres per min., and

n = No. of cycles required

Now, Cutting speed (v) = Length of cutting stroke/ Time taken in cutting stroke

Cutting time = Length of cutting stroke/ Cutting speed in m / min .

= L/ v1 min.

or,

= (l + l1 + l2)/ v1 min.

And, non-cutting time or idle time

= Length of cutting in metres/ Return speed in m/min = L/ v2

= l + l1 + l2 / v2 min.

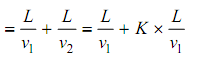

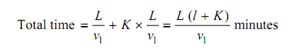

Now, Total time per cycle = Cutting time + Idle time

Equation 1

{where K = ratio of idle stroke time to cutting stroke time)

Equation 2

For shaping a workpiece an allowance of around 5 mm is left on either side of it. Therefore, the shaping width of the workpiece is attaining as:

Shaping width B = Width of workpiece + 2 × allowance

No. of cycles required (n) = Shaping width/ Feed per cycle = B/ f

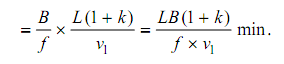

Machining time = No. of cycles × time required for each cycle

Equation 3