Stationary Phases:

The stationary phase used in TLC can be an adsorbent, an ion exchanger, a molecular sieve or it can serve as the support for a liquid film. It consists of a finely divided powder of particle size 5 to 50 µm. A huge variety of stationary supports are available for coating the smooth surface of glass, plastic or metal. Plastic sheets have the benefits that these can be easily cut to any shape or size as required l. Silica gel G (60-120 mesh) remains the most frequently used coating materia. It contains hydroxyl groups on the surface which form hydrogen bonds with polar molecules. The adsorbed water prevents other polar molecules from reaching the surface. Hence, the gel is activated by heating to remove the adsorbed water. Within modified silica gel, H and OH groups could be replaced through other functional groups similar to bonded phase. Alumina containing hydroxyl groups or oxygen atoms is another commonly used adsorbent. Other adsorbents widely used are powdered cellulose, magnesium silicate, calcium silicate, activated charcoal, natural diatomaceous earth, ion exchange resins such as Dowex- 50W-strong acid cation exchanger in sodium or hydrogen form and Dowex-1-strong base anion exchanger in chloride form. Kieselghur is frequent used for the separation of sugars. Actually, any adsorbent material that can be used in adsorption or column chromatography can be used in TLC.

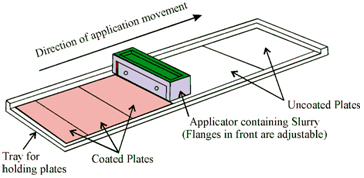

Here, aqueous slurry of the powder is prepared by mixing the adsorbent with a binder such as plaster of Paris (CaSO4) and polyvinyl alcohol to help it adhere to the backing material. It is uniformly spread over the plate manually or by using one of the commercial forms of spreader as shown in Figure. The thickness of the layer is usually in the range 0.1 to 0.3 mm but for preparative work much thicker layers are preferred. The solvent is evaporated off and adsorbents are activated by placing in an oven at 110o C for a few hours. The Precoated ready-to-use plates and sheets are also commercially available.

Figure: Apparatus used for preparing TLC plates where the applicator is filled with the slurry of adsorbent and binder in a solvent.