Compound Cylinders:

In order to decrease the hoop stresses developed in thick cylinders subjected to large internal pressure, compound cylinders along with one thick cylinder shrunk over the other are utilized. With calculated junction pressure among the two cylinders, this is possible to decrease the hoop stress and to make it more or less uniform over the thickness. Lame's expressions are applied to the inner and outer both cylinders before and after the introduction of the internal fluid pressure, and in the two stages the stresses are superposed to attain the final values. While the outer cylinder is shrunk over the inner cylinder, the difference among the inner diameter of the outer cylinder and the outer diameter of the inner cylinder find out the shrinkages pressure developed at the junction. Assume rj be the common radius at the junction after shringing on. Assume Sr1 be the difference among the outer radius of inner cylinder and rj and Sr2 be the difference among rj and inner radius of the outer cylinder.

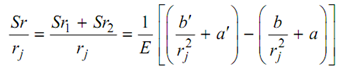

If in the radii Sr be the difference before shrinking on, then we get

Sr = Sr1 + Sr2

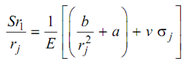

For inner tube, the circumferential strains at the common radius rj is provided by

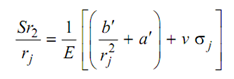

where σj is the junction pressure because of shrinkage. Likewise, for the outer cylinder,

(tensile)

Thus,

That means the original difference of radii at the junction shall be specified by the algebraic difference among the hoop stresses for the tubes at the junction multiplied by the junction radius divided by E.