Thermal Stresses

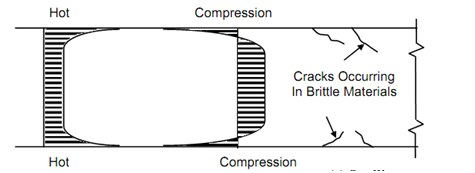

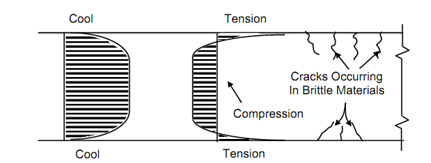

The reason why thermal stresses come into existence is explained in Figures (a) and (b). In the first case it is illustrated that outer surface of the material is at higher temperature that its inside. This produced a thermal gradient across the thickness. The surface layer tends to expand whereas the inner material applied restrain upon it and does not permit the surface to expand. Consequently the surface material experiences compressive stress whereas the inner material is subjected to tension. Combined along loss of yield strength at higher temperature the surface material might develop cracks at 45oC (due to shear). In the second case while outer surface is at lower temperature than inside the surface material may develop tension while the inner material may be subjected to compression. It might result in surface cracks normal to the direction of tension.

(a) Results of Surface Heating in a Flat Slab

(a) Temperature (b) Stresses (c) Spalling

(a) Temperature (b) Stresses (c) Spalling

(b) Results of Surface Cooling in a Flat Slab

Figure: Residual Stresses Created due to Differential Heating and Cooling in a Flat Slab

The above examples illustrate how the thermal gradient introduces stresses in the material. As a general rule across a thermal gradient the hot region is under tension whereas the cold one is under compression. Thermal stresses arise in any body that is heated & restrained from expansion. The restrain might be provided by part of the body at lower temperature as illustrated above or it might be because of external bodies connected to the body in question. Welded joints are the good instance of restrains from outside. The materials made up of more than one material having different coefficient of thermal expansion also suffer from thermal stresses while heated. The bimetallic strip utilized for thermostatic control is very common example. In various practical applications insulating materials in furnaces or liquid metal ladle linings are subjected to such effects. Most refractory material being brittle are greatly in danger of developing surface crack due to thermal residual stresses. Reduction or ignoring of such cracking calls for proper structural design as well as selection of material.