Thermal Shock

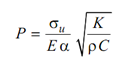

Steep change in temperature might cause sudden application of high stress upon the material being heated or cooled. Though, sudden and fast cooling is more dangerous than heating because cooling of outer surface results in tensile stresses on the surface. The surface is weaker than the inside and is subjected to higher stress and worse operating conditions. This situation is much more risky in case of refractory bricks that are brittle materials. This resistance to thermal shock that is measured in terms of force (P) has been found to be function of ultimate specific heat (C) ,tensile strength (σu), coefficient of thermal expansion (α), density (ρ), modulus of elasticity (E), and thermal conductivity (K). High value of K will permit heat to pass through the body and therefore improve P. On the contrary the lower values of E, α, ρ and C shall help increase the value of P, the thermal shock resistance. It is of great importance to note that refractory materials have low ultimate tensile strength in addition to low thermal conductivity. Reduced thermal shock resistance results in spalling of surface caused by compressive stresses because of fast heating. Pyrex glass & fused silica have low value of α and thus better thermal shock resistance. Metals apparently shall have high thermal shock resistance because of higher σu and K values. Plastic materials contain low values of σu and E and therefore better thermal shock resistance.

The most important single factor that will ensure safety in high temperature application is to avoid high heating rate, & also large cross-section on thickness of body to be heated up. The shock resistance is given by