Insulators

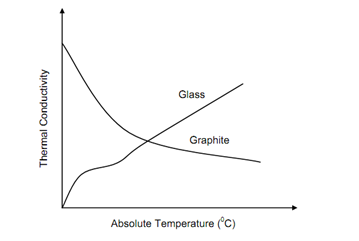

Thermal insulators are needed in industrial practices, equipment & domestic appliances. Such materials are basically those which do not have free electrons in their structure & heat conduction in only because of lattice vibration in form of elastic waves. Such elastic vibrations are influence by impurity atoms and defects as grain boundaries, vacancies and dislocations. The interference among elastic waves & defects also causes anisotropy of heat conductivity. This is easy to understand that in crystalline materials the interference shall reduce with reducing temperature with consequent enhance in thermal conductivity Such interferences do not exist in amosphous materials like glasses & plastics and thus their thermal conductivity increases with rising temperature. Figure illustrates variation of thermal conductivity of a few solids utilized at high temperatures. The general insulating materials are mixtures of cellular, granular of fibrous bodies with voids filled with air. Air as a bad thermal conductor, these porous materials is good insulator.

Figure: Schematic Variation of Thermal Conductivity

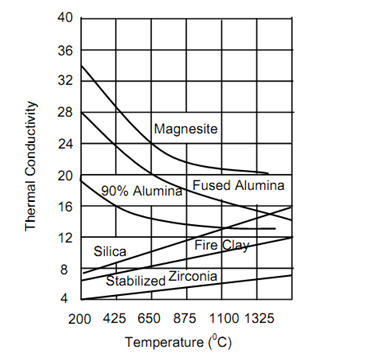

The insulating materials are divided in four groups. Low temperature insulators are for use up to 10oC. Porous polymeric materials might carry gases which freeze in pores to produce vacuum. Vacuum is much better insulator in that this terminates elastic wave. Such insulators are utilized for cryogenic applications. Building insulators are utilized in the range of 10oC to 150oC. Generally these are plastics & wood. Industrial insulators compose the group that are utilized between 150oC to 315oC. Bricks, concrete are primarily utilized in this range but are often further insulated by minerals, glasses, slag wools and various inorganic powders filled among sheets. High temperature insulators are that group that is utilized above 315oC. Porous ceramic bricks for refractory and ceramic powders are utilized as insulators at these temperatures. Insulating bricks may not sustain flames directly but firebricks might withstand flame.

Figure: Thermal Conductivity as Functions of Temperature

Porous polymeric materials reach very high insulating properties at low temperatures. Porous refractories or ceramic powder insulators are used in high temperature applications specifically above 550oC. For practical applications insulators are classified as loose fill, ready to fit & rigid insulators. Loose fill insulators are applied to structure like pouring or foaming. The materials utilized are minerals, slag wools, glasses, & inorganic powders etc. Foamed plastics such as isocyanate might also be utilized as loose fill insulator. Ready to fit insulators make use of paper sheets, cloth sheets or wire mesh between which fibrous materials are enclosed. Rolls of blankets of ready to fit insulators are commercially available for use in building and industry. Wood, sugar cane fibres corkboard, foam glass, foamed plastics and rubber might be formed into boards or slabe which work as rigid insulators. Insulating bricks are rigid insulators also. The outer surface of insulators utilized for high temperature insulation, shall attain temperature higher than surroundings. It shall cause heat loose by convection and radiation modes of heat transfer.

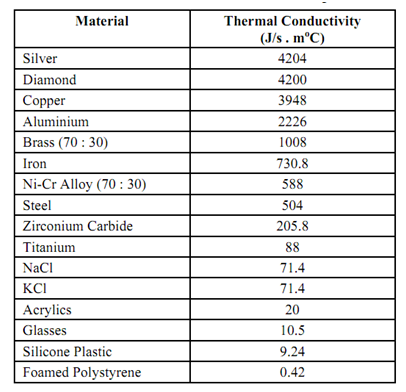

Table describes thermal conductivities of a few materials at room temperature, giving ideas regarding material selection as conductor or insulator.

Table: Conductivities at Room Temperature