Synchronous Manufacturing:

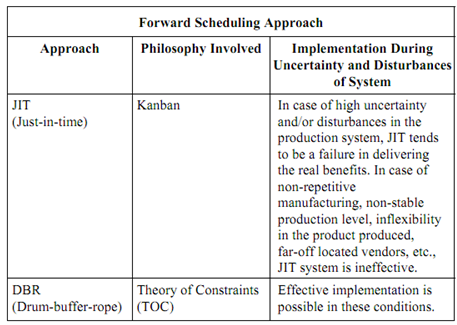

Synchronous manufacturing is a comparatively newer approach, which utilizes forward scheduling to direct the production/manufacturing system. Just-in-time (JIT)-based system of kanban-approach and Drum-buffer-rope (DBR) based system of TOC-approach are the two common kinds of forward scheduling approaches. MRP, alternatively, is a backward scheduling approach.

Table: Forward Scheduling Technique

Synchronous manufacturing utilizes TOC as a way to incorporate forward scheduling .It focuses on critical resources so that time-wise forward scheduling is completed; Non- bottleneck or non-critical resources are utilized to resolve critical constraint.

Process-batch size and transfer-batch size are modified in synchronous manufacturing to reduce lead time and WIP. A backward scheduling technique, such like MRP, may not perform this task.