Constraints:

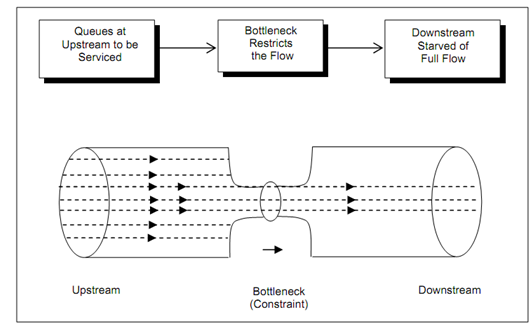

The throughput of a manufacturing system shall naturally increase until it is limited by some constraints or bottleneck. Normally, a bottle is narrowest at its neck and therefore the flow through the bottle is restricted by the size of its neck. Resource, that is bottleneck (also, termed as constraint), is the major cause of low flow of material through all the processes (or, throughput). Goldratt, in his preliminary work, utilized the term "bottleneck" to describe a Limiting-machine. Later, he realized the fact that in a complicated system, several things are associated. These are following: resources, manufacturing and non-manufacturing, schedules, capacities, so on. In these systems, the recognition of real bottleneck is hard. He utilized the term constraint to describe restriction that restricts throughput and goal. He considered bottleneck as a point or storage in the manufacturing process that holds down the amount of product that a factory can produce. This is where the flow of material, being acted on, narrows to a thin stream.

Figure: Effect of Constraint on the Flow (or Throughput)

A machine, which is always busy will limit the throughput of the entire plant. An extremely skilled or specialized operator or a very costly tool may be the bottleneck.