Toughness and Resilience

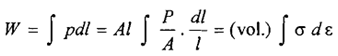

Because the force, which pulls the tension test specimen, the force is causing movement of its point of application thus the work is done. It work is stored in the specimen and can be measured like:

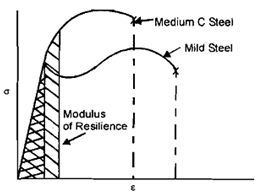

Apparently the quantity ∫s de is the energy stored in the specimen per unit volume and is nothing but the area under the s-e curve, up to any point toughness is regard as capability of a material to absorb strain energy during elastic and plastic deformation. The resilience is similar capacity within elastic range. 'The maximum toughness will apparently be at fracture, which is the area under entire s-e diagram. This energy is named as module of toughness. Likewise the maximum energy absorbed the specimen in elastic limit is called modulus of resilience. This is the energy absorbed the tension specimen when the deformation has reached points a in diagram. But since in most materials the proportional limit, elastic limit points a and b in diagrams seem to coincide along with yield stress as shows in diagram, the modules of resilience is the area of triangle as shown in given diagram.

Diagram of Resilience and Toughness for Two Materials

It can be seen that modulus of resilience is greater for medium carbon steel than for mild steel, whereas modules of toughness of two materials may be closely similar. Medium carbon steel apparently has higher UTS and YS however smaller percent elongation along with respect to mild steel. High modules of resilience are preferred for such machine parts, which are needed to store energy. Springs are good illustration. Thus, springs are made in high yield strength materials.