Impact Strength

Impart is a rapidly applied load. A notched specimen is broken beneath impact loading in an impact test. The state or condition of stress at notch is complex, actually tri-axial and impact load causes a high strain rate. The combination of these two makes the material to behave in a brittle manner and raises the yield strength. Hence the fracture occurs before yielding. This is often not easy to calculate the stress at notch and thus the energy absorbed in fracturing the specimen is measured as the material property and is described a name as impact strength. Such a value cannot be utilized for designing but this is an indicator of the fact as to how much tendency the material has to behave as brittle material. The machine for a test consists of a swinging hammer, such through a free fall is allowed to strike a notched specimen in a way to stress notch in tension. The potential energy of hammer before striking that is in its raised position can be calculated and also the potential energy of the hammer after striking and purposing the fracture of the specimen can be calculated from the height reached by hammer at the end of its swing. The difference of two potential energies minus loss of energy in moving through air is the energy absorbed by the specimen in fracturing. The energy is the impact strength of material of specimen.

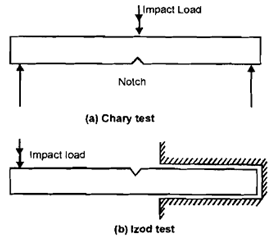

Two configuration of notched specimen are in common employing and they are shown in given diagram. Charpy test employs the specimen is simply supported beam while Izod test utilizes the specimen as cantilever. In both the cases the load is applied to that notch, is in tension. A 10 millimeter x 10 millimeter x-section bar supported over a span of 40 millimeter a carrying a Y-notch of depth equal to 113 of the depth of section is a common Charpy test specimen. To compare results from various sources standardization of specimens is necessary. An Izod specimen might be circular or rectangular in section.

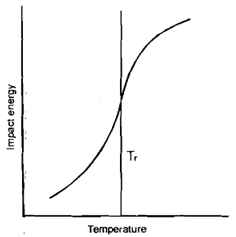

Separately from two worst situation, viz. of notch and impact, which render specimen brittle a third situation to be explored is temperature. The material tends to as become brittle at low temperature and therefore performing impact tests on notched specimens at various temperature is imperative. The results of a test are depicted in given diagram wherein the impact strengths are plotted as like function of temperature. The results apparently centre on a temperature T, displaying that for T > T, the impact strength rises fast but for T < T, it reduces fast. That temperature is called transition temperature as this represents the transition from ductile to brittle nature as like temperature reduces. The operation of a machine part or structural component close to transition temperature on higher side carries a risk that if temperatures reduce slightly the material may start behaving in a brittle manner. Impact tests are often helpful in establishing transition temperature. The reasons could be to avoid such a temperature or to choose a material whose transition temperature is upper or higher than the operating temperature. The material most susceptible to its transition is mild steel and this material is largely utilized for structures. The non-ferrous material as like alloys of Al and Cu do not show such transition from ductile to brittle. For evaluating performance of welded mild steel tests are often performed since the milk steel welded structures are often utilized in ship building. The ship has to operate in cool and warm climates.

Diagram of Influence of Temperature upon Notched Bar Impact Energy