RTD Construction:

The RTD incorporates pure metals or certain alloys which increase in resistance as temperature raise and, conversely, decrease in resistance as temperature decreases. The RTDs act somewhat like an electrical transducer and converting changes in temperature to voltage signals through the measurement of resistance. The metals which are best suited for use as RTD sensors are pure, of uniform quality, stable within a provided range of temperature and able to provide reproducible resistance-temperature readings. Just a few metals have the properties necessary for use in RTD elements.

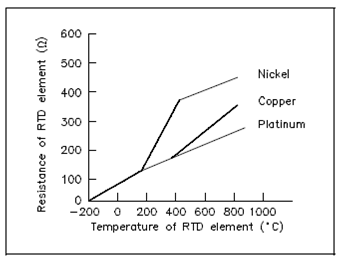

Figure: Electrical Resistance-Temperature Curves

RTD components are generally constructed of platinum, nickel, or copper. These metals are best suited for RTD applications since of their linear resistance-temperature features (as display in Figure), their high coefficient of resistance, and their ability to withstand repeated temperature cycles.

A coefficient of resistance is the change in resistance per degree change in temperature, commonly expressed as a percentage per degree of temperature. The materials used have to be capable of being drawn into fine wire so in which the element could be simply constructed.

RTD elements are commonly long, spring-like wires surrounded through an insulator and enclosed in a sheath of metal. Figure displays the internal construction of an RTD.