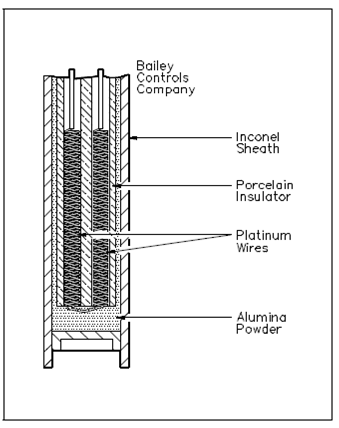

Internal Construction of a Typical RTD:

This particular design has a platinum element which is surrounded through a porcelain insulator. The insulator avoids a short circuit among the wire and the metal sheath.

Figure: Internal Construction of a Typical RTD

Inconel, a nickel-iron-chromium alloy that is commonly used in manufacturing the RTD sheath since of its inherent corrosion resistance. While placed in a liquid or gas medium, the Inconel sheath rapidly reaches the temperature of the medium. The change in temperature would cause the platinum wire to cool or heat, resulting in a proportional change in resistance.

This change in resistance is then measured through a precision resistance measuring device which is calibrated to provide the proper temperature reading. This device is generally a bridge circuit that will be covered within detail later in this text.

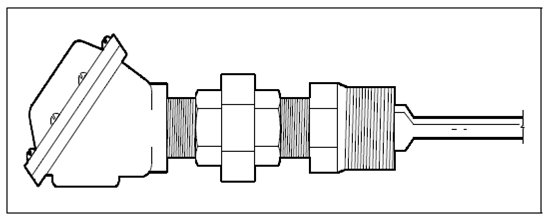

The above figure displays an RTD protective well and terminal head. A well protects the RTD from damage through the gas or liquid being measured. Protecting wells are generally made of stainless steel, cast iron, Inconel, carbon steel, or and they are used for temperatures up to 1100°C.

Figure: RTD Protective Well and Terminal Head