Types Of Manufacturing Systems

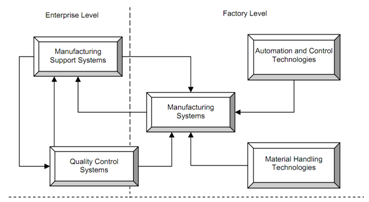

A manufacturing system is explained as a collection of human resources and integrated equipment, such function is to perform one or more processing and or assembly operations on a beginning raw material, part, or set of parts. The integrated equipment comprises production machines and devices, material handling and work positioning tools, and computer systems. Human resources are essential either full time or periodically to maintain the system running. The figure specified below illustrates a manufacturing system placed in the bigger production system.

Figure: The Position of the Manufacturing System in the Large Production System

In manufacturing systems, the term workstation is utilized to refer to a location in the factory, here some well-defined operation or task is accomplished. A particular manufacturing system may contain of one or more workstations. A system along with multiple stations is termed as a production line, or machine cell, or assembly line depending upon its function and configuration.

A manufacturing system contains of various components. Such are classified as:

(a) Production machines, related hardware, fixtures, and other tools,

(b) Material handling system,

(c) Computer systems to organize or and control the above components, and

(d) Human workers.

The particular description of each of these components is described below: