Deformation of Cubic Structures:

Whether or not a material can deform plastically at low applied stresses depends on its lattice structure. It is simpler for planes of atoms to slide through each other if those planes are closely packed. Thus lattice structures along with closely packed planes permit more plastic deformation than those which are not closely packed. Also, cubic lattice structures permit slippage to occur more simply than non-cubic lattices. This is since of their symmetry that gives closely packed planes in various directions. The majority metals are made of the body-centered cubic (BCC), hexagonal close-packed (HCP) crystals, or face-centered cubic (FCC) described in more detail in the Module 1, Structure of Metals. A face-centered cubic crystal structure will deform more readily under load before breaking than a body-centered cubic structure.

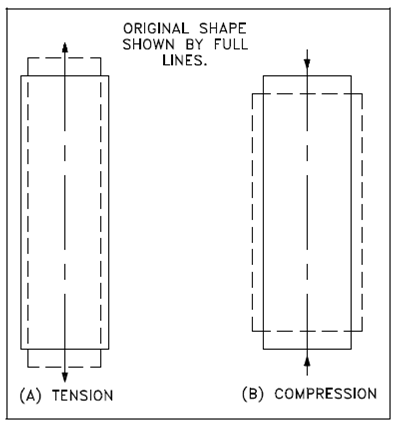

Figure: Change of Shape of Cylinder Under Stress

The BCC lattice, while cubic, is not closely packed and forms strong metals. α-iron and tungsten have the BCC form. A FCC lattice is both cubic and closely packed and forms more ductile materials. α-iron, gold, silver, and lead are FCC structured. At last, HCP lattices are closely packed, other than not cubic. HCP metals such as cobalt and zinc are not as ductile as the FCC metals.