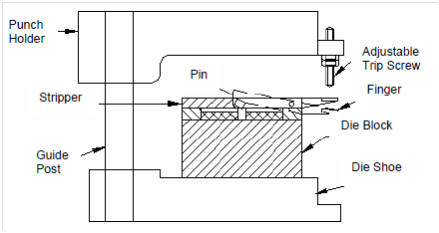

Automatic Stop

Automatic stop is display in Figure. It uses pin-ended finger. On the forward stroke, the pin end of finger is lifted through the trip screw. The pin end of finger is dropped onto the top surface of the stock during return stroke. The finger is mounted loosely on pivot so in which it can move endwise. Because of this endwise movement of the finger, its pin end does not drop onto the top surface of the stock instead of within the former position. The pin drops into the further blank, as the stock is fed forward. That helps the operator to locate the stock strip accurately.

Figure: Compound Die

Simultaneous blanking and piercing is achieved through giving blanking and piercing element in both the member of die, that is. the upper and the lower member of the die. These elements are set actually opposite to every other so in which piercing punch acts in the opposite direction along with respect to the blanking punch. In this way blanking & piercing operations are performed concurrently. Angular clearance is given in the piercing die. This helps in simply removal of scrap from the die. The blanking punch acts as a piercing die. The sidewall, that is adjacent to cutting edges of blanking die opening, is straight so in which the blank does not pass by the die. Knock out stroke is actuated during the return stroke of the press. It ejects the blank. Compound dies are slow in operation but provide close tolerance on workpiece.

The flatness of the blank is achieved during cutting operation through knock out plate.

Large elements can be blanked in a smaller press through using compound die. In compound die, extremely high force is required. Design of punch and die is also hard for number of operation (more than five). Compound die is brilliant for two operations.