Martempering

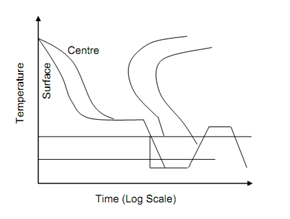

The piece to be hardened is fully austenised and then quenched into a lead of salt bath held at a temperature just above the at which martensite would begin to form. It is kept at this temperature until its temperature becomes uniform throughout (i.e. outside and inside temperatures do not remain different) and is then water quenched to form complete martensite structure and bainite formation is prevented. This process successfully separates the cooling contraction from the austenite-martensite expansions and thus prevents quench cracking in large articles. The process of martempering is shown in Figure.

Figure: Martempering Shown on the TTT Curve

The steel can be tempered to low temperatures to further refine the structure.

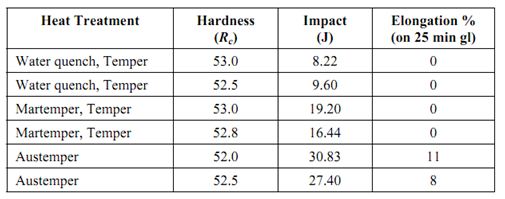

Table describes a few properties obtained from quenchtemper, austemper and martemper treatments.

Table: Some Mechanical Properties of 0.95 C, 0.40 Mn Steel at 20oC after Different Treatment