Isothermal Transformation

Austenite is not generally converted into martensite immediately but the process continues for sometime. Different steels take different time for full transformation and the time based upon the temperatures from where cooling is begun. How to achieved isothermal transformation diagram was discussed in detail in previous Section. The selected specimen is austenised and after that quenched in liquid bath held at temperature to be investigated. The specimen is held for a different length of time in the bath and after that quenched in the water. The resulting structure may be studied under microscope or any other linked property like hardness might be studied. It is seen that definite times are needed for the initiation and completion of the transformation and these times vary with the temperature. The progress of transformation, say for 10%, 50% or 90% might also be found.

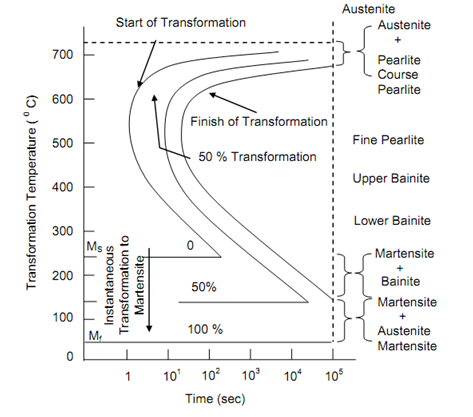

Figure reproduced with more details, illustrates full transformation diagram of eutectoid steel. As the transformation temperature is lowered from A1 temperature to about 550oC, the nucleation & completion time reduce and pearlte and lamellae become finer. From about 550oC to 250oC, the nucleation & completion time enhance. The transformation product here is termed bainie that is composed of two equilibrium phases that are ferrite and cementite. The time of minimum nucleation is recognized as the nose or knee. Below about 250oC the transformation product is martensite. This forms almost instantly, but the amount formed based upon the temperature. The upper & lower limits of martensite transformation temperatures are termed MS and MF temperatures. These diagrams are also known as Time-Temperature-Transformation or TTT diagrams and were discussed earlier. They are also referred to as S-curve because of their shape.

Figure: Isothermal Transformation Diagram for a Eutectoid Steel. Structures Present after 105 Seconds are given on the Right-Hand Side