Processing Sequences for Common Engineering Materials

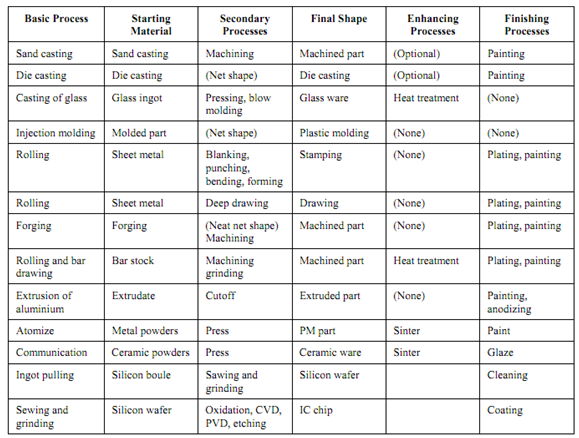

Table 1 below presents some distinctive processing sequences for common engineering materials utilized in manufacturing.

Table 1: Some Typical Process Sequences

In most cases parts and materials arriving at the factory have completed their basic process. Therefore the first operation in the process plan follows the basic process that has provided the starting geometry of the part. For example, machined parts begin as bar stock or castings or forgings, which are purchased from outside vendors. The process plan begins with the selection of basics part followed by the machining operations in the company's own plant. Stampings begin as sheet metal coils or strips that are bought from the rolling mill. These raw materials are supplied from outside sources so that the property-enhancing operations, finishing operations and secondary processes might be performed in the company's own factory.

In addition to the route sheet, a more detailed description of each operation is prepared usually. This is filed in the specific production department office where the operation is performed. It defined specific details of the operation, such as cutting conditions and tooling (if the operation is machining) and other instructions that may be useful to the machine operator. The descriptions often include sketches of the machine setup.