Grading:

The particle size distribution in a given sample of aggregate is termed as grading of the aggregate. The grading of aggregates could be conveniently described along with the help of grading curves. Grading Curve is a curve displaying variation of cumulative percentage of passing (on Y-axis) over the different size of sieves (on X-axis in log scale).

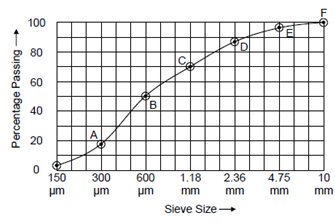

The grading curve for the data, obtained in Table 2, is display in Figure 4. The steep slope of the grading curve, which is from A to B (i.e. between 300-600 μm size), indicates the greater proportion of these size particles in the sample. The uniform slope of the grading curve, which in this case is from B to D (i.e. between 600 μm-2.36 mm), indicates the continuous grading, i.e. particles of all sizes (between 600 μm-2.36 mm size) are present in the sample. Flat slope of the grading curve, which is from D to E (i.e. between 2.36-4.75 mm), indicates lesser/negligible contribution of the particles of that size. Horizontal portion of grading curve, which in this case is between E to F (i.e. between 4.75-10.00 mm), indicates that the particles of this size (i.e. 4.75-10 mm) are almost absent in the sample.

Figure: Grading Curve for Table

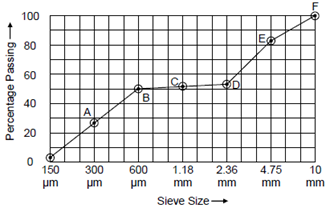

Figure: Gap Graded Aggregate

The horizontal portion of the grading curve represents Gap-Grading. For example, the curve in Figure 5 represents the gap-graded aggregate in which the particles of size 600 μm-2.36 mm are almost absent.

Comments

A single numerical value or a mathematical formula cannot specify the good grading of aggregate. Actually, one should go for actual trial and error procedure in order to obtain reliable/satisfactory grading. The good grading of aggregate basically implies that the aggregate sample is having required proportion of all standard fractions of the aggregate so that sample contains minimum voids and provides least surface area. This will require minimum cement paste to fill these voids, that is need of cement and water will be reduced and will lead to better economy, greater strength, less shrinkage and more durability of concrete. Also, proper care should be taken in selecting the grading so as to avoid segregation. Generally, the workability of concrete is governed more by grading of fine aggregate rather than the coarse aggregate.