Sewer Rehabilitation

Non-repairing of sewers renders them leaky; and, as a result they carry large volumes of infiltration water. They must often get blocked and sometimes even collapse. The expenditure of excavating and then replacing a portion of badly functioning sewer is prohibitive. It is, therefore, economical to repair and rehabilitate the system as such. Therefore, continuing sewer maintenance efforts have to be designed with a view to prevent unnecessary deterioration of the sewer system. Any maintenance programme that may be adopted depends on the nature of the problem, necessity of maintaining the flow while the repair is being carried out, the expected traffic disruption that may be caused, safety aspects that need to be addressed, and the cost that has to be borne.

It is necessary to clean the sewer lines before embarking on a visual inspection. This is commonly done by flushing the sewer by using a fire hose, connected to a hydrant that discharges into a manhole. However, caution is to be applied to avoid backups into the surrounding buildings that are connected to the system. There is yet another method to clean the sewers using a soft rubber ball that is inflated to match the diameter of the pipe and later being pulled by a cord via the reach of the line between manholes. Power rodding machines or power winches (to pull a bucket through the line) can also be used. It is essential to ensure that the collected debris is disposed of properly. Inspections (after cleansing operations) are made during low-flow periods using flashlights. Use of closed-circuit television system (even making a photographic or videotape record) gives accurate location of leaks, root intrusions, and any structural problems.

A common method for sealing leaks in otherwise structurally sound pipelines comprises of chemical grouting. The grout is applied internally to joints, holes, and cracks. In smaller or medium sized lines, inflatable rubber sleeves are generally pulled through, while in large sized lines workers place a sealing ring manually over the defective joint, and the grout is pumped through a hand held probe. However, as a safety measure, the air in the sewer must be tested for carbon monoxide, hydrogen sulphide, and explosive gases before allowing entry to workers.

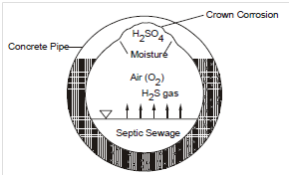

Crown corrosion (Figure 19) can cause structural damage to sewers. Large sewers, suffering this damage can be strengthened by applying a lining of gunite – a mixture of fine sand, cement, and water. It is applied internally by means of pneumatic spraying. Long lengths of concrete sewers are effectively rehabilitated with gunite lining. To renew an extensively cracked sewer lines, a procedure known as sliplining is adopted. It comprises of pulling a flexible plastic liner pipe into the damaged pipe and then reconnecting all the individual service connections to the liner. Sometimes it may be necessary to fill the narrow annular space between the lines and the existing pipe with ground preventing relative movement. However, it may be pointed out that multiple excavations are required to reconnect each service line to the new liner. In a relatively new and sophisticated method, namely, Inversion lining, a flexible liner is used. This line expanding to fit over the pipe geometry is thermally hardened. This procedure avoids excavations for service line connections.

Figure 6.19: Crown Corrosion in Unlined Concrete Sewer

Concrete manholes may also suffer sulphuric acid corrosion. Severe cases may need total replacement of the manhole. For less severe cases, the deteriorated material is removed using water or sand blasting, or mechanical tools, and then special chemical preparations are applied to stabilize the remaining material. Next, high strength patching mortar is used for filling in the irregularities in the internal surface; and, lastly, a lining or a coating has to be applied.

Manholes are sometimes subject to surface water inflow and/or ground water infiltration. It is an unacceptable situation. This can arise due to holes in the manhole cover, spaces between the cover and the frame, and poor sealing of the frame of the cover. Frames can be resealed using hydraulic cement, and waterproof epoxy coating. Sometimes the manhole frame and cover are raised, and the exposed portion is coated with asphalt or cement. Another method consists of installing a special insert between the frame and the cover. It does not allow water and grit to enter the manhole while allowing gas to escape through a relief valve.

The problem of infiltration of ground water through the sidewall of a manhole and its base, or around pipe entrances is solved by chemical grouting, being a less costly method compared to lining or coating. It needs no preparatory restoration of the surface and the cracks and opening get sealed by pressure injection of the gel or foam (grouting materials).

House (service) connections of smaller diameter pipes; join the lateral sewer line in the street. These house lines are also known as building sewers or service laterals, and can be as long as 30 m. These can develop defects like cracks and open-jointed pipes, causing considerable infiltration of ground water. The total length of service connections can often be greater than the length of the main sewers. Therefore, the maintenance of these lines is also equally important. Chemical grouting and inversion lining procedures are often helpful.