Process Selection Considerations

A summary of the factors involved in process selection is following, in the form of questions to be answered throughout this stage:

- Have all alternative manufacturing processes been investigated?

- Are the methods selected economical for the type of material, the shape to be produced, and the needed production rate?

- Can the requirements for surface finish, dimensional tolerances, and product quality be met consistently?

- Can the part be shaped and formed to final dimensions without using additional processes?

- Are secondary processes such like grinding, machining and finishing necessary?

- Is the tooling required available in the plant? May it be purchased as a standard item?

- Is scrap produced? If so, how may it be minimized? What is the volume of scrap produced?

- Are all processing parameters optimized?

- Have all the computer-control and automation possibilities been explored for all of phases of the manufacturing cycle?

- Can group technology be implemented for parts with similar geometric and manufacturing attributes?

- Are inspection techniques & quality control techniques being implemented properly?

- Is it essential that all component of the product be manufactured in-house? Is it possible to buy some parts as standard items from external sources?

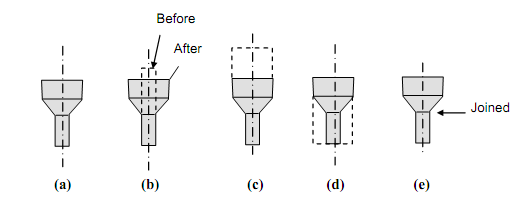

Figure 7 : Several Methods of Making a Simple Part : (a) Casting or Powder Metallurgy, (b) Forging or Upsetting, (c) Extrusion, (d) Machining and (e) Joining Two Pieces