Causes of Inefficiency

In this portion we will compare some of the kinds and reasons for the inefficiencies of real components and cycles to that of their "ideal" counterparts.

Components:

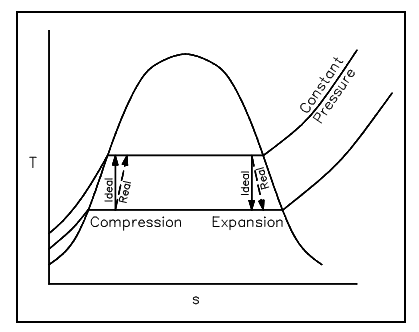

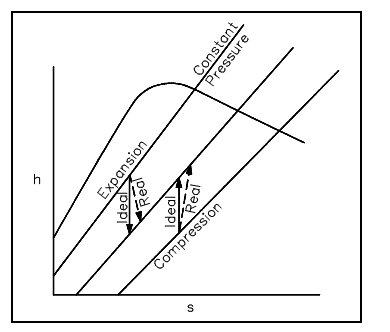

In real systems, the percentage of overall cycle inefficiency is due to the losses by the separate components. The pumps, turbines, and compressors all behave non-ideally due to friction, heat losses, and windage losses. All of such losses contribute to the non-isentropic behavior of real tools. The losses as shown in figures below can be seen as a rise in the system's entropy or quantity of energy which is unavailable for employ by the cycle.

Figure: Expansion and Compression procedures on T-s Diagram

Figure: Expansion and Compression procedures on h-s Diagram

Cycles:

In real systems, the second source of inefficiencies is from compromises made due to cost and other factors in the operation and design of the cycle. Illustrations of such kinds of losses are: In a large power generating station the condensers are designed to sub-cool the liquid by 8-10°F. This sub-cooling permits the condensate pumps to pump the water forward without cavitations. Though, each degree of sub-cooling is energy which should be put back by reheating the water, and this heat (i.e., energy) does no helpful work and thus raises the inefficiency of the cycle. The other illustration of a loss due to a system's design is heat loss to the atmosphere that is thin or poor insulation. Once more this is energy lost to the system and hence unavailable to do work. The friction is another real world loss, though resistance to fluid flow and mechanical friction in machines. All of such contribute to the system's inadequacy.