Johnsons Rule:

In manufacturing environment this procedure is termed as sequencing of N number of jobs on two resources or machines. It aims to minimize the total production time and idle time of the system under consideration. Step-wise implementation of Johnson's rule includes the following .

Table: Stepwise Implementation of the Johnson Rule

|

Step 1 List all of the jobs and times for each work-center or machine

|

|

Step 2 Choose the job having the shortest activity time

|

|

Step 3 If the activity chosen lies under first work centre, schedule the job first

|

|

Step 4 If the activity chosen lies under the second work centre, schedule the job last

|

|

Step 5 The selected job should be eliminated from the list

|

|

Step 6 Repeat steps 2-5, till all selected job get scheduled

|

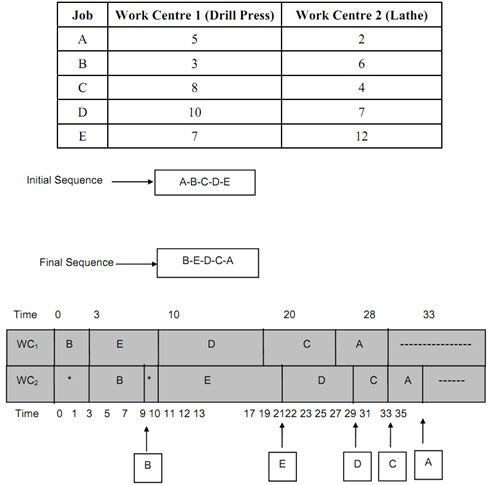

An example defining the Johnson's rule is shown in Table

Figure: A Detailed Example of Johnson's Rule