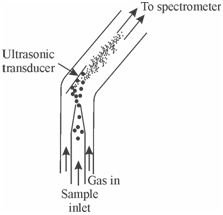

Ultrasonic nebulisation:

In this case the sample is pumped on to the surface of a piezoelectric crystal that vibrates at a frequency of 20 kHz to a few MHz. The waves so produced are very efficient in turning the sample into a fine aerosol, which is carried by a stream of argon, first through a heated tube and then to a refrigerated tube to condense out the solvent. Such nebulisers produce more dense and homogeneous aerosols because of desolvation and there is no cooling effect. This improves detection limit by a factor of 10 to 20 as compared to pneumatic nebulisers.

Figure: Schematic diagram of an ultrasonic nebuliser