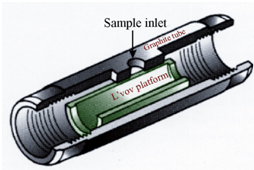

Electrothermal vaporisation:

An electrothermal vaporiser (ETV) is an evaporator located within a closed chamber through that an inert gas such as argon flows to hold the vaporised sample within the atomiser. The sample could be vaporised from an ETV on a conductor such as carbon rod or a tube furnace or a heated metal filament generally used in AAS. A schematic diagram of an L'vov platform used as electrothermal vaporiser is given in Figure. In compare to the nebuliser arrangements, ETV system generates a discrete signal rather a continuous one so in which signal from the atomised sample increases to a maximum and then decreases to zero as the sample is swept by the atomiser. Every preheated electrode is introduced within the aperture of a preheated cuvette and heated through means of a separate power supply. It enables 1-200 µL samples to yield around a sequence of improvement within detection limit in the range 0.1-500 pg. The main problems of electrothermal atomisation system are interferences because of sample matrix.

Figure: Schematic diagram of L'vov platform-an electrothermal vaporiser in a graphite furnace