Microwave Digestion:

In another method of preparing sample for AAS determination, microwave radiations are employed. A microwave digestion system (MDS) offers more rapid and efficient decomposition of complex matrices of geological and biological samples. The concept of microwave ovens for the decomposition of inorganic and organic samples was first proposed during mid 1970s. This method has an advantage over conventional methods as it takes less time because of rapid heating ability of microwaves.

In contrast to conventional flame/hot plate heating method based on conduction, microwave energy is directly transferred to all the molecules of solution almost simultaneously without heating the vessel and thus boiling temperature is reached very quickly due to increased pressure in the vessel. In addition, small amounts of reagents are used and evaporative losses are avoided, thus reducing interferences by reagent contamination. As MDS could be simply automated it greatly reduces the operator time to prepare samples for analysis. These days multi-vessel MDS with 4, 6 or 8 vessels are commercially available where more number of samples can be simultaneously dissolved.

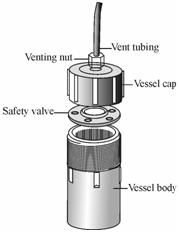

Microwave digestion vessels are constructed from low-loss materials that are transparent to microwave radiation. A teflon is an ideal material for several of the acids involving HF commonly used for dissolution. Not just it is transparent to microwaves but it has low melting point of ~300 oC which is of course lower than boiling point of H2SO4 and H3PO4. For those acids, quartz and borosilicate glass vessels are used. A typical closed vessel microwave digestion system consisting of teflon body, cap and a safety relief valve is shown in Figure. The maximum recommended temperature obtained with this device is 250ºC. When overpressurisation occurs, safety valve gets distorted similar to home pressure cookers and the excess pressure is released.

Figure: A schematic diagram of closed vessel microwave digestion system

Commercially available MDS incorporates corrosion protection for the interior along with variables like as sample mass (0.1-2g), digestion acids (HCl, HF, HNO3 and H3BO4), power setting and heating time (1-20min), etc.