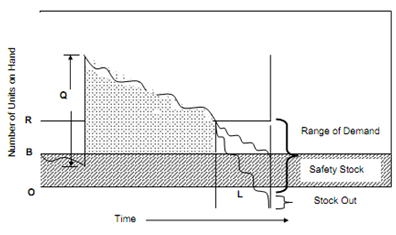

Fixed-order Quantity Model with Safety Stock:

Inventory level is monitored perpetually by the fixed-order quantity system and it places a new order while stock reaches some level R. During Lead time among the time an order is placed and the time it is attained, there is danger of stock out in the model. It is depicted in Figure that an order is placed while the inventory position drops to the reorder point, R. During this lead time L, a range of demands is possible.

Figure: Fixed-order Quantity Model with Safety Stock

The major difference lying among a fixed-order quantity model where demand is known and one where demand is uncertain is in computing the re-order point. The amount of order quantity remains similar in both of the cases. The uncertainty element is taken into account in the safety stock.

The reorder point is given by

R = d¯L + z σL

where d = Average daily demand,

z = Number of standard deviations for a specified service probability, and

σL = Standard deviation of usage during lead time.

The term z σ L accounts for the amount of safety stock. The +ve sign of safety stock mentioned that its effect is to place a reorder is sooner.